Referencing many posts from The Oil Drum, a blog often frequented by petroleum engineers and other oil-industry specialists, David Phillips lays out a worst case scenario for the Deepwater Horizon Oil Well. Hopefully this has been proven false by the successful static kill procedure completed in mid August.

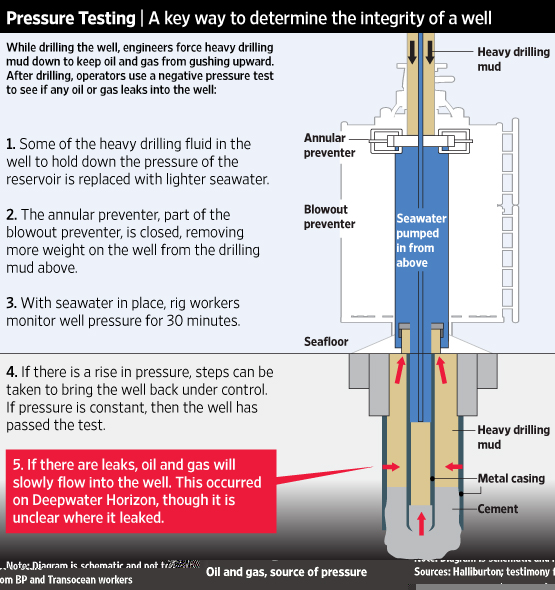

Phillips contends the well’s casings beneath the ocean floor have been irreversibly damaged, possibly to such an extent that it may be impossible to cap the well.

He adds:

We know little about the underlying geology of the spill site since BP has held that information close, claiming that it’s “proprietary” data. Scientists are clamoring for BP to publicly release geological survey data on the underlying “Lower Teriary” formations (rock layer formed 65 million to 250 million years ago). Remotely operated vehicles (ROVs) are streaming video feeds of high pressure columns of oil and gas bubbling up from fissures in the sea floor — flowing from likely stress fractures in the underground piping.

Evidence cited by Phillips include the tilting BOP at 12-15% from vertical after the riser was removed, the fact that particulates have sand blasted the wells and well-liners for over 70 days while the well spewed oil into the gulf, and other anecdotes from The Oil Drum blog.

Larry Flak, an engineer recognized the world over for his acumen in containing deepwater well blowouts, presciently warned back in 1997 (before drilling at depths of 30,000+ feet was feasible) of the dangers ultra-deepwater blowouts might pose:

Underground blowout risk is substantial in ultra deepwater wells…. Blowout control options in ultra-deepwater are very limited. Blowout prevention is of paramount importance.